Distributed Control System Simulation Software Free Download Updated FREE

Distributed Control System Simulation Software Free Download

SimulationX

SimulationX

Design and Analyze Your Multi-Physics System with Simulation Software

Technical systems, like machines and manufacturing plants, are often very circuitous. They consist of a multitude of components and subsystems, usually based on various technical domains and increasingly fitted with sensors and controls. Their dynamic interactions accept a significant impact on safety, performance, and comfort.

With SimulationX, you take a single platform for modeling, simulating, and analyzing technical systems, including mechanics, hydraulics, pneumatics, electronics, and controls, likewise as thermal, magnetic, and other physical behavior. Comprehensive component libraries with application-oriented model elements ensure you have the right tools available for your job.

Benefits of SimulationX

- Shorten development fourth dimension by using models to quickly test the effects of diverse design changes

- Save costs by using virtual prototypes instead of building physical prototypes

- Develop and test command software and hardware with a virtual constitute before the system is built (SiL, MiL, HiL)

- Carry out extensive simulation-based experiments to identify potential design problems early, when the cost to change is small

- Create a digital twin of the system that tin can run in parallel to the existent system to monitor system condition and identify faults

Nosotros had to be sure information technology would work before we congenital a prototype. The results of the simulations gave united states of america the confidence nosotros needed to go on with the commissioning. It was fascinating to follow the correlation between the previously simulated behavior and the measurements!"

Strategic Projects / Hatebur Umformmaschinen AG, Switzerland

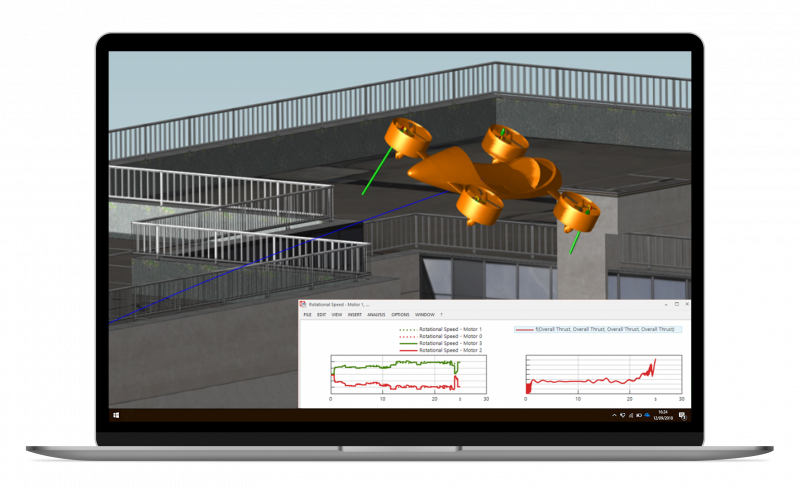

SimulationX for Aerospace

SimulationX is a sophisticated platform to efficiently model, simulate, and analyze mechanical, hydraulic, pneumatic, electrical, and combined systems. From the concept to detailed evolution to virtual tests, obtain reliable results on the physical behavior apace and efficiently. The lumped chemical element simulation method enables you to model and simulate even large and circuitous systems rapidly, economically, and reliably.

As a development partner in the MISSION project (Modelling and Simulation Tools for Systems Integration on Shipping), which is role of the European program "CleanSky2", we are working towards the goal of elaborating and establishing a model-based process throughout all phases in the development of aircraft with the aid of a sophisticated development environs.

Benefits of SimulationX for Aerospace Applications

- Create next-generation aircraft actuation systems with small, lightweight, powerful batteries, electrical motors and generators

- Pattern free energy efficient environmental control systems

- Develop, optimize, and control test benches for components and systems for aircraft and spacecraft

- Equip your training simulators with realistic and physically correct behavior

- Model and simulate complex systems towards hydrogen-based aviation

- Develop reliable bulldoze and altitude control systems of satellites and spacecraft to ensure design and performance for extreme atmospheric condition

- Assess safety and reliability with fault tree analyses (FTA) and failure mode and event analyses (FMEA) based on system models

- Integrate with requirements management and system architecture to create a traceable model-based systems applied science (MBSE) framework that fulfills strong certification requirements for safety and reliability supported by virtual testing

More Information

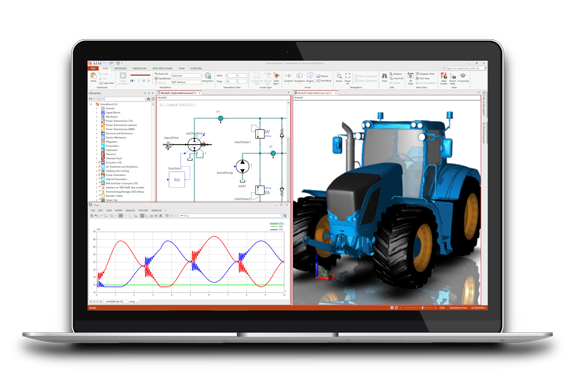

SimulationX for Automotive

What might the drivetrain of future vehicles look like? How high are ability density, energy efficiency, flexibility, vehicle dynamics, and driving condolement? How do several physical systems interact with each other, and how can mechatronic correlations be described comprehensively? How can I rapidly simulate thermal loads in electrical and hybrid vehicles without having to perform a tedious and time-consuming series of measurements? What is the optimum capacity and performance of my battery in terms of costs, installation space, range, and service life? These and other questions can no longer exist answered through measured data. Model your multiphysics systems and conduct virtual tests in SimulationX - from the modeling of drive systems, chassis and vehicle dynamics simulation to efficiency analyses of gearboxes and energy efficiency in general.

Benefits of SimulationX for Vehicle Evolution

With the multiphysics simulation software SimulationX, you are in full command of a vehicle's electronics and mechatronics interactions.

- Design and evaluate conventional, hybrid and electrical drive systems including battery and thermal management and operating strategies

- Predict and minimize 1D to 3D vibrational phenomena (NVH: noise vibration harshness)

- Design reliable safety & comfort systems e. g. active steering, tailgates, windshield wipers, side mirrors

- Investigate vehicle dynamics e. g. for active and passive vehicle interruption systems (including kinematics & compliance)

- Develop efficient powertrains from drive to cycle incl. lateral and longitudinal vehicle dynamics

- Evaluate transmissions with focus on shifting behavior, as well as gear rattling and whining

- Assess powertrain vibrations and torque ripple originating from the electric automobile and inverter

- Configure the battery stacks taking into account the electrical, thermal and aging characteristics of the cells

- Virtually test and optimize control strategies with real-time capable driveline and vehicle models (SiL, MiL, HiL)

- Efficiently simulate, test and analyze the function of Avant-garde Driver Assistance Systems (ADAS) taking into account environmental and road conditions

More Information

SimulationX for Energy Engineering

The high energy density in power plants, transmission paths, and storages must be constantly bachelor while remaining safety for human being and the environment. From diverse projects, we know the complex requirements with respect to energy efficiency, the integration of renewable energies, and safety. Our simulation solutions offering you a solid foundation for simulating and analyzing fluid power, thermodynamic, mechanical, and electrical systems in order to meet all of these requirements – fast, safely, and efficiently.

Benefits of SimulationX for Energy Technology

- Analyze power plant technology and processes – from bulldoze technology and mechanical transmission of power to load scenarios and safety studies

- Design energetically optimized buildings considering their environs and managing interactions of energy sources, consumers and storage systems

- Optimize the operation of hydrogen compression and storage plants

- Forecast renewable energies, from geothermal to hydrogen to solar, optimizing integration into existing grids and validating energy storage scenarios

- Simulate HVAC engineering science in vehicles, mechanism, and buildings

- Evaluate the dynamic behavior of components and systems used for oil & gas production, covering systems; drilling (top-side and subsea), production (top-side and subsea) and subsea construction and procedure equipment

- Perform reliability analyses and establish Mistake Tree FTA of an oil & gas system to place the weakest link and bottlenecks in the system

SimulationX for Mobile Machinery

With such a vast number of requirements, accurate analyses of transient, nonlinear processes are becoming increasingly vital. For such considerations, it is usually non enough to simply await at stress analyses, menses calculations, or cinematic simulations. Mobile machines like excavators, wheel loaders, agricultural and forestry mechanism, road construction equipment, physical mixers, concrete pump systems, cranes and hoisting gear, compression, and tunnel irksome machinery are mechatronic systems. Likewise mechanical parts, they consist of hydraulic actuator systems and the corresponding control units. Many undesirable effects during operations have their cause in a weak interaction of the sub-systems from various concrete domains. Particularly the high number of nonlinear processes in mobile machinery is hardly manageable through measurements alone whatsoever longer.

Benefits of SimulationX for Mobile Machinery

- Compare and analyze conventional, electric, and hybrid drive systems

- Optimize hydrostatic bulldoze and steering systems

- Design and automate performance-evaluation of autonomous construction equipment

- Develop and test controller components with respect to functional and energetic aspects early in the design phase

- Calculate forces and moments interim on winches and pulleys of hoist and break ropes with respect to rope properties (east.1000. length, mass, tensile strength) and load profiles

- Check compliance with certification-related condom requirements (east.g. stability)

- Identify optimization potential for crane pattern in line with industry standards such as EN 13000 and EN 13001

- Create training simulators with physically correct behavior of the machine

- Maximize operator comfort by analyzing vehicle dynamics

SimulationX tin can exist applied to several other industries. For information on yours, click the links below.

Distributed Control System Simulation Software Free Download

DOWNLOAD HERE

Source: https://www.esi-group.com/products/system-simulation

Posted by: matthewsmaraver1971.blogspot.com